In this page, we are providing Fibre to Fabric Class 7 Extra Questions and Answers Science Chapter 3 pdf download. NCERT Extra Questions for Class 7 Science Chapter 3 Fibre to Fabric with Answers will help to score more marks in your CBSE Board Exams.

Class 7 Science Chapter 3 Extra Questions and Answers Fibre to Fabric

Extra Questions for Class 7 Science Chapter 3 Fibre to Fabric with Answers Solutions

Fibre to Fabric Class 7 Extra Questions Very Short Answer Type

Question 1.

Of which nutrient silk fibre is made?

Answer:

Protein

Question 2.

What are silkworms?

Answer:

Silkworm are caterpillars of silk moth.

Question 3.

What are larvae called?

Answer:

Caterpillars or silkworms

Question 4.

What is the process of taking out silk threads from the cocoon called?

Answer:

Reeling the silk

Question 5.

Where is reeling done?

Answer:

In special machines

Question 6.

What spins the cocoons inside which develops the silk moth?

Answer:

Caterpillar or silkworm

Question 7.

How many eggs do a female silk moth lay at a time?

Answer:

Hundreds of eggs.

Question 8.

Where are the eggs stored?

Answer:

The eggs are stored on strips of cloth or paper

Question 9.

Why are moths reared?

Answer:

Moth are reared for obtaining silk.

Question 10.

Why are cocoons collected?

Answer:

Cocoons are collected to get silk threads.

Question 11.

Where are larvae kept in the process of rearing?

Answer:

Larvae are kept in clean bamboo trays.

Question 12.

In which country silk industry begun?

Answer:

China

Question 13.

What is silk route?

Answer:

The route, the traders and travellers travelled to introduce silk to other countries is called silk route.

Question 14.

Which country leads the world in silk production?

Answer:

China

Question 15.

Name two varieties of silk.

Answer:

Tassar silk and mooga silk

Question 16.

What is the nature of silk fibre obtained from the cocoon of mulberry silk moth?

Answer:

It is soft, lustrous and elastic.

Question 17.

What is pupa?

Answer:

The next stage of caterpillar in the life cycle of silk moth is called pupa.

Question 18.

What is sericulture?

Answer:

The rearing of silkworms for obtaining silk is called sericulture.

Question 19.

What is cocoon?

Answer:

The silky covering spun by the larvae of silkmoth for protection as pupae is called cocoon.

Question 20.

Name two wool yielding animals.

Answer:

Yak, sheep.

Question 21.

Name two finished products of wool.

Answer:

Sweater, shawl.

Question 22.

Name two types of fibres of the hairy skin of the sheep.

Answer:

The coarse beard hair and the fine soft under-hair close to the skin.

Question 23.

What are occupational hazards?

Answer:

Risks faced by the workers in any industry are called occupational hazards.

Fibre to Fabric Class 7 Extra Questions Short Answer Type

Question 1.

What keeps the wool yielding animals warm?

Answer:

The wool yielding animals like sheep, goat, yak, etc., have a thick hair on their body. Hair trap a lot of air. Air is a poor conductor of heat, which does not allow the heat absorbed to release from their body and keeps them warm.

Question 2.

Explain selective breeding.

Answer:

In some animals, to get desired characters in offsprings parents are selected having that desired characters for breeding. This process is known as selective breeding. For example, some breed of sheep are selected for their soft under-hair.

Question 3.

There are other sources of wool except sheep. Explain.

or

Mention other sources of wool than sheep.

Answer:

The fleece of sheep is not the only source of wool. There are some other sources for obtaining wool. Such as yak wool is common in Tibet and Ladakh. Angora wool is obtained from angora goats found in hilly regions. Wool is also obtained from camel hair. Llama and Alpaca found in South America also yield wool.

Question 4.

Explain rearing and breeding of sheep.

Answer:

Sheep are reared in many parts of the country for obtaining wool. Sheep are herbivores and so they feed on grass and leaves and other products like pulses, corn, jowar, oil cakes, etc. In winter season, they are kept indoors and feed on leaves, grain and dry fodder. Some sheep are ‘selectively bred, with one parent being a sheep of good breed for obtaining specific characteristics in their off spring.

Question 5.

What is shearing? Explain.

Answer:

Once the reared sheep have developed a thick growth of hair, it is shaved off for getting wool. The process of removing the fleece (hair) of the sheep along with a thin layer of skin from its body is called shearing. It does not hurt the sheep.

Question 6.

What is scouring? Explain.

Answer:

In the process of making wool from fibres, scouring is done after shearing. The sheared skin with hair is thoroughly washed in tanks to remove grease, dust and dirt. This is called scouring. Nowadays, it is done by machines.

Question 7.

Define sericulture.

Answer:

Silk fibres are animal fibres obtained from cocoons of the silkworm. The rearing of silkworms for obtaining silk is called sericulture. It is a very old occupation in India.

Question 8.

What is called reeling the silk?

Answer:

When the cocoons are kept under the sun or boiled or exposed to steam, the silk fibres separate out. The process of taking out threads from the cocoons for use as silk is called reeling the silk. It is done in special machines, which unwind the thread or fibres of silk from the cocoon.

Question 9.

How are the silkworms reared?

Answer:

Silk moths are reared and their cocoons are collected to get silk threads. The eggs laid by a female silk moth are stored carefully on strips of cloth or paper and sold to silkworm farmers. The farmers keep eggs under hygienic and suitable conditions of temperature and humidity.

Fibre to Fabric Class 7 Extra Questions Long Answer Type

Question 1.

Describe in brief about the animals that yield wool.

Answer:

The animals that yield wool are sheep, yak, goat, camel, etc. The wool commonly available in the market is sheep wool. Yak wool is common in Tibet and Ladakh. Angora goats yield angora wool, which are found in hilly areas such as Jammu and Kashmir.

The under fur of Kashmiri goat is soft and so it is woven into fine shawls called Pashmina shawls. The hair on the body of camels is also used as wool. Llama and Alpaca also yield wool. They are found in South America. Wool obtained from different animals and based on their quality are used to make different kinds of woollen things.

Question 2.

What are the various steps for processing fibres into wool?

Answer:

The processing of fibres into wool involves various steps such as shearing, scouring sorting, dyeing and rolling. They have been discussed below in brief:

Step 1. Shearing: First of all, the woollen coat or fleece from the animals along with a thin layer of skin is removed from their body. The process is called shearing.

Step 2. Scouring: The sheared skin with hair is thoroughly washed in tanks to remove grease, dust and dirt from the wool. This is called scouring.

Step 3. Sorting: It is done after scouring. The hairy skin is sent to a factory where hair of different textures are separated or sorted.

Step 4. The small fluffy fibres called burrs, are picked out from the hair. The fibres are scoured again and dried. Now the wool is ready to be drawn into fibres.

Step 5. The fibres are dyed in various colours because the natural fleece of sheep and goats is black, brown or white.

Step 6. Finally the fibres are straightened, combed and rolled into yarn. The longer fibres are made into wool for sweaters and the shorter ones are spun and woven into the woollen cloth.

Question 3.

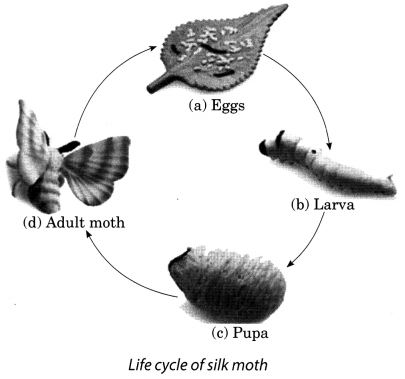

Describe the life history of a silk moth with the help of figures of each stage.

Answer:

Silk fibres are also known as animal fibres. They are soft, light in weight and strong. Silk fibres are obtained from the cocoons of the silk moth or silkworm. The life history of silk moth involves mainly four stages:

Eggs ➝ Caterpillars or Silkworms ➝ Pupa ➝ Adult silk moth

The female silk moth lays eggs, from which hatch larvae called caterpillars or silkworms. They grow in size and when they are ready to enter the next stage called pupa, they first weave a net to hold themselves. Then they swing their heads from side to side in the form of the figure 8.

During these movements, they secret fibres made of a protein which hardens on exposure to air and becomes silk fibre. Soon the caterpillars completely cover themselves by silk fibres and turn into pupae. This covering is known as cocoon. The further development of the pupae into moths continue inside the cocoons. Moths are reared and their cocoons are collected to get silk thread for obtaining silk.

Question 4.

Describe how silkworms are reared and silk is processed.

or

Mention the process of getting silk from cocoon.

Answer:

Silk moths are reared and then cocoons are collected to get silk threads for obtaining silk. A female silk moth lays hundreds of eggs which are stored carefully on strips of cloth or paper and sold to farmers. The farmers keep the eggs under hygienic conditions and under suitable conditions of temperature and humidity.

The eggs are warmed at certain temperature for the larvae to hatch from eggs. This is done when mulberry trees bear a fresh crop of leaves. The larvae called caterpillars or silkworms, eat up these leaves and grow rapidly and increase enormously in size. The larvae are kept in clean bamboo trays along with freshly chopped mulberry leaves.

After 25 to 30 days, the caterpillars stop eating and move to a small chamber in the tray to spin cocoons. The caterpillars or silkworms spin the cocoons inside which develops the silk moth. The cocoons are kept under the sun or boiled or exposed to steam. The silk fibres separate out. Silk fibres are then spun into silk threads, which are finally woven into silk cloth by weavers.

Fibre to Fabric Class 7 Extra Questions HOTS

Question 1.

Why is silk obtained by mulberry silk moth most popular?

Answer:

Silk obtained by mulberry silk moth is most popular because of its shimmering appearance which produces different colours.

Question 2.

You have been asked to buy a woollen sweater from the market. How will you check its purity.

Answer:

We can test the purity of the woollen sweater by burning it. Take about 10 cm long thread (spare one). Hold it with the help of a tong and burn its one end. If the fibre smells like burning hair, it is wool but if . the fibre smells like chemicals or burning plastic, it is artificial wool.

On blowing out of the flame touch the end of the fibre. If the end turn to dust on touching then it is pure wool but if the end has melted and turned hard, then it is not pure wool.

Question 3.

Why natural fibres are costlier than synthetic fibres?

Answer:

Natural fibres are obtained either from plants or animals. The process of obtaining fibres from these natural sources is comparatively labour intensive process than production of synthetic fibres on large scale from other raw materials or chemicals.

Question 4.

Compare the properties of silk and wool.

| Silk | Wool |

| (i) Silk is smooth, soft and lustrous. | (i) Wool is dense, soft, curly, elastic and resilent. |

| (ii) It is more sensitive to heat. | (ii) It is less sensitive to heat. |

| (iii) It is made up of protein called fibroin. | (iii) It is made up of protein called keratin. |

| (iv) It is strongest natural fibre. | (iv) It is stronger but less than silk. |

| (v) Silk can be worn in both hot and winter season. | (v) Wool is worn only in winter season because it traps body heat and keep us warm. |

Question 5.

What are occupational hazards? What occupational hazards are linked with wool and silk production?

Answer:

Health risks faced by the workers of a particular occupation or industry are called occupational hazards. In wool industry, wool sorter’s can get infected by a bacterium which causes fatal blood disease, called anthrax or sorter’s disease. In silk industry workers handling dead worms with bare hands may get infection. Fine hair on caterpillars may cause asthma or conjunctivitis.

Fibre to Fabric Class 7 Extra Questions Value Based (VBQs)

Question 1.

Sania got upset on learning that for obtaining 1 kg of raw silk around 5,000 cocoons are killed. But her mother explained her that silkworms are also conserved in this process for obtaining silk next time. Also it is the source of income to many rural and needy person.

(a) Why silk are famous?

(b) Whom do you agree- Sania or her mother? Why?

(c) If you get an option to select between a silk dress and a dress made of synthetic fibre which one will you select and why?

(d) What value of Sania is shown here?

Answer:

(a) Silk are famous for its smooth and lustrous fibre which is also strong.

(b) Do it yourself.

(c) Hint: While selecting dress one should always keep in mind the advantages and disadvantages of natural and synthetic fibres.

(d) Sania is eco-friendly, sensitive and concern for other creatures.

Question 2.

Many occupational hazards are associated with wool and silk production. Most of these hazards can be prevented by just having a proper awareness and knowledge of how to tackle such conditions. The main reason for occupational hazards in India is due to poverty, illiteracy and poor hygienic conditions.

(a) What occupational hazards are associated with wool and silk industries?

(b) How can most of the occupational hazards be minimised?

(c) What values of people are shown here?

Answer:

(a) 1. Wool industry: Anthrax or sorter’s disease

2. Silk industry: Infections, asthama and conjunctivitis

(b) Occupational hazards can be minimised by

1. taking precaution while handling animals like wearing gloves, mask, using disinfectants, washing hands, etc.

2. having proper knowledge and awareness of signs and symptoms of diseases of human and animal.

(c) People are ignorant, careless and illiterate.